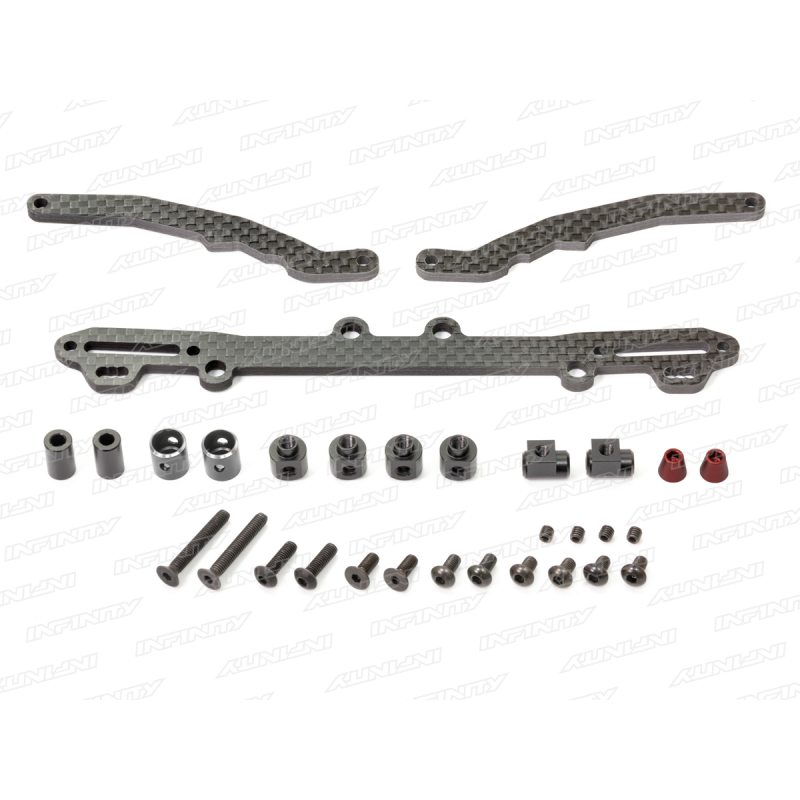

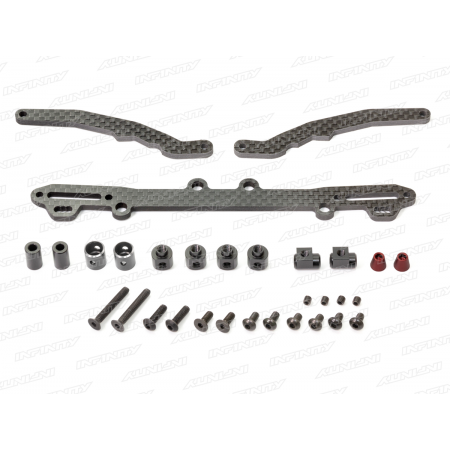

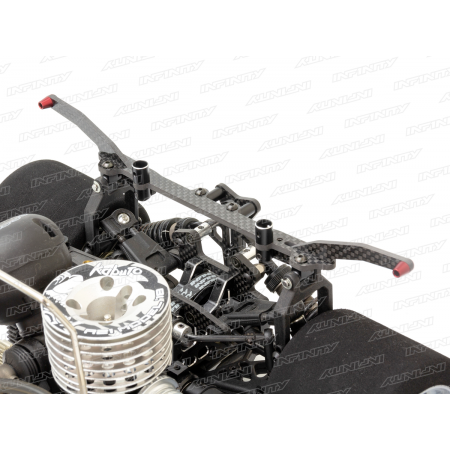

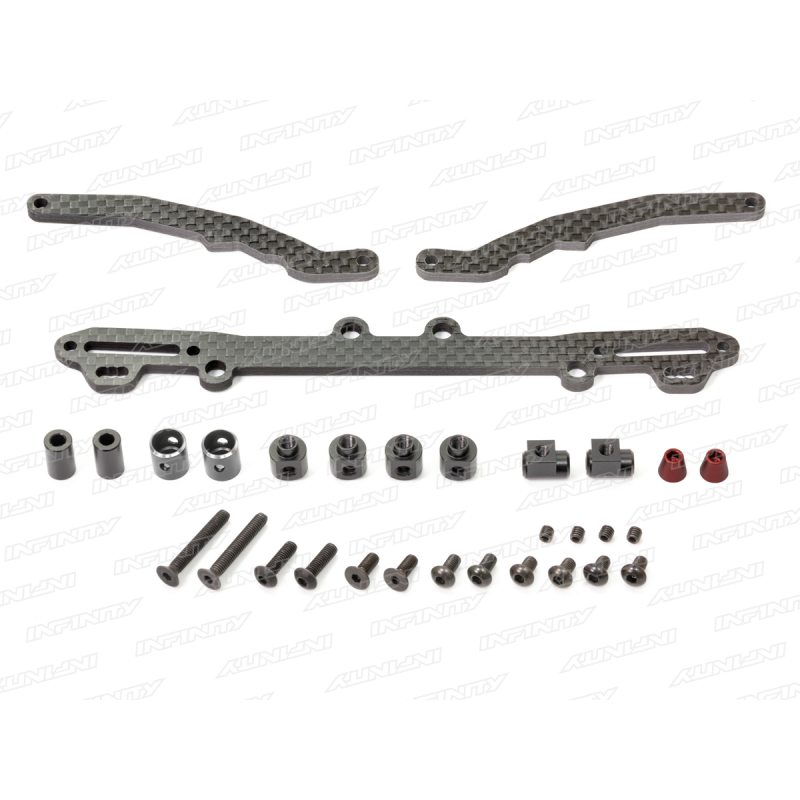

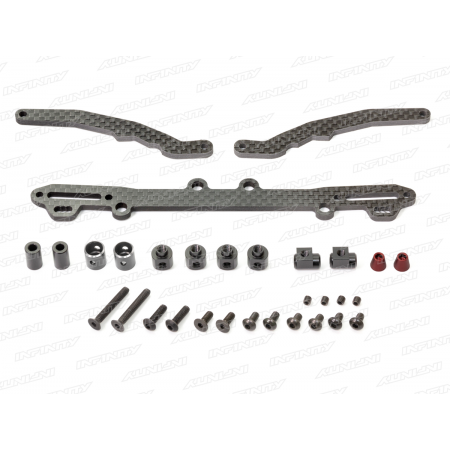

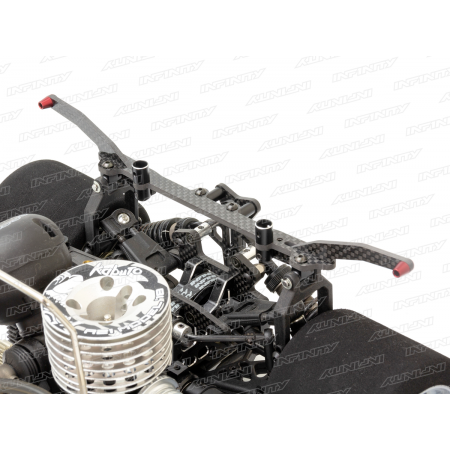

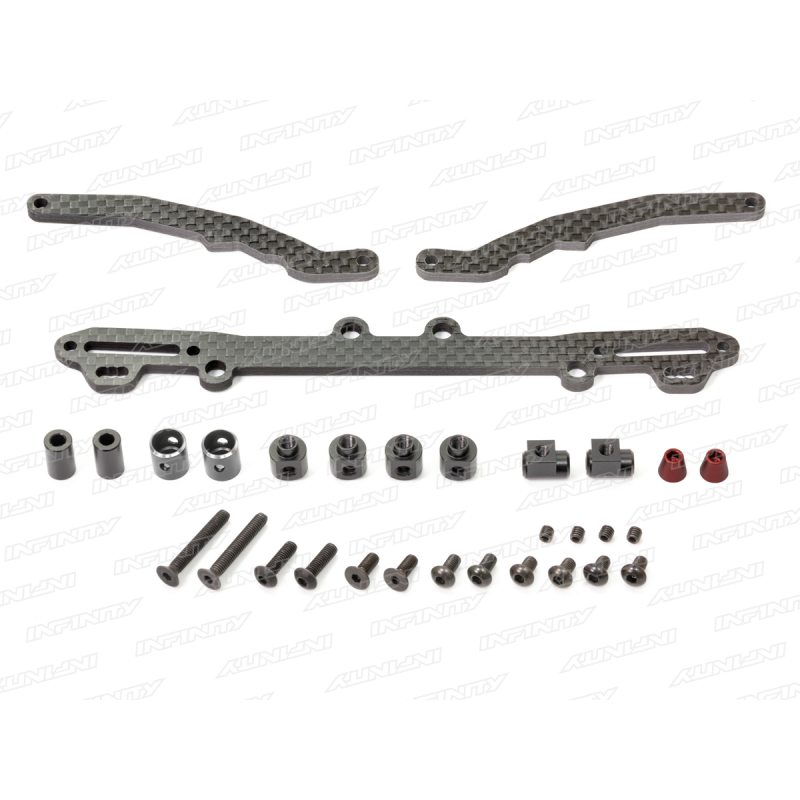

Compared to the standard plastic rear body mount, this new carbon mount increases the height of the body by 3mm (Almost the limit within the regulation of IFMAR). In addition, the cross-sectional shape of the carbon plate and A7075 adapter matches the latest body shapes such as XTREAM's Diablo and Protoform's R19 without any gaps. This allows the downforce to be transferred to the tires without loss and improving rear grip. The left and right carbon plates can be fine-tuned with set screws to accommodate individual body shapes. The connection to the car body can be made in three step width directions, and also absorbs the twisting of the mounting part when toe-in is applied.

To change ackerman angle (more increase angle of outside front tyre)

Machined from high quality A7075 aluminium material. IF18-2 knuckle upper and lower insert. Prevents misalignment during a crash and enhances steering response during cornering. This bushing is used for central alignment of the upper pivot (0mm kit standard zero offset).

When assembling these parts first remove the front knuckle upper. Place the offset bush into the knuckle upper from the outside. Then pass both M3x14mm slim head screws through the knuckle upper from the inside and tighten the 3mm nylon nut on the outside.

By moving the 3x11.8mm pin position of the universal shaft through

90 degrees this allows for a more free drive transmission at high RPM and a smoother suspension

movement under high load, overall offering an increased steering feel.

A vivid red anodized version has been added to the aluminum spacer series (3mm in inner diameter). It helps you dress up your machine. If you use this red anodized version and the black version in different specifications in a setting, you can easily distinguish them.

A new aluminium servo horn designed specifically for IF18. 25T specification for servos made by Savox (SC2271SG) and Futaba (BLS371SV). By making the shape of the arm offset it is possible to achieve the maximum steering angle with a linear steering operation. Use in combination with R0259 Aluminium servo saver (up side).

Bearing support rigidity has been greatly improved by increasing the roundness of the bearing cavity area as much as possible using a special molding process that has never been used before. This provides a higher consistency of rear traction.

This carbon plate is used in combination with R00220L long front body post to increase the rigidity around the front bulkhead. Response in initial steering is increased while still maintaining a mild steering feel in the middle part of the corner. Also offering a weight saving of 4g the standard kit body mounting.

Uses a softer material than the standard R0303-01.

Steering response is more mild and easy to drive.

Installing this part significantly improves rigidity to the rear section of the chassis around the gear area, enabling more reliable power transmission, increasing acceleration and top speed. In addition to this the increased pitching rigidity of the chassis helps to add initial response and a sharper steering feel.

Option part for Infinity IF18. This brake disc offers a more stable braking performance during long runs. The disc is made from thicker material than the standard item and also vented to efficiently dissipate heat. Improved brake feeling, spring included.

An all new front one way set featuring larger one way bearings for improved durability. The timing of the drive transmission to the front tires has also been changed resulting in milder and more easy to drive characteristics. The overall weight has been reduced to 24g, 4g lighter than the original.

Compared to the standard plastic rear body mount, this new carbon mount increases the height of the body by 3mm (Almost the limit within the regulation of IFMAR). In addition, the cross-sectional shape of the carbon plate and A7075 adapter matches the latest body shapes such as XTREAM's Diablo and Protoform's R19 without any gaps. This allows the downforce to be transferred to the tires without loss and improving rear grip. The left and right carbon plates can be fine-tuned with set screws to accommodate individual body shapes. The connection to the car body can be made in three step width directions, and also absorbs the twisting of the mounting part when toe-in is applied.