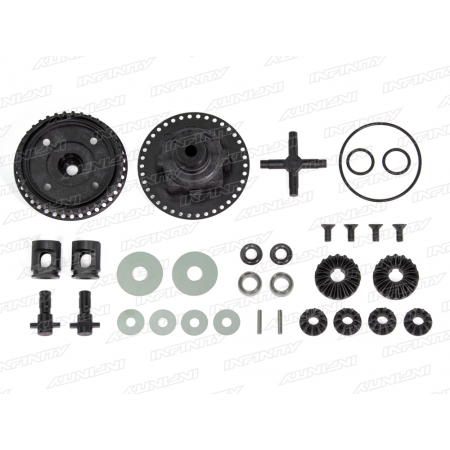

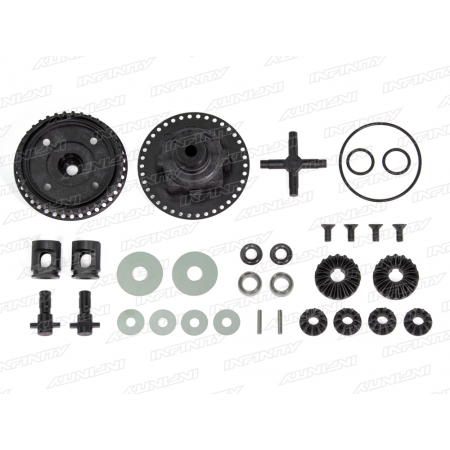

The newly designed gear differential for IF14 offers smooth rotation and high rear traction in all conditions. The differential shafts are now supported by ball bearings for added stability and consistency during runs. Outdrive cups can now be replaced from the outside without the need to open the diff making maintenance quick and easy.

0.75mm thinner than kit normal(5mm). Usefull to make the width narrow.

We recommend using the Chassis Mounted Alu. Steering Post when better steering response is needed. INFINITY red anodized production visually effects everyone.

This is a set of 4.9mm ball ends made of strong and high-precision hard steel. The screw part is shorter than the 5mm ones. The ball surface is smoother than that of the conventional one (T049), yet sold at a competitive price.

This is a set of 4.9mm ball ends made of strong and high-precision hard steel. The screw part is shorter than the 7mm ones. The ball surface is smoother than that of the conventional one (T050), yet sold at a competitive price.

By adding these wheel shims between the hex wheel hub and the wheel, you can fine-tune the cars track width quickly. Available in two thicknesses of 0.25mm and 0.5mm. 8pcs are included in each.

This is a set of 4.9mm ball ends made of strong and high-precision hard steel. The screw part is shorter than the 9mm ones. The ball surface is smoother than that of the conventional one (T051), yet sold at a competitive price.

This high flex top deck is slim and designed to keep high rigidity during pitching and still maximize chassis flexibility. The deck becomes more flexible during the latter half of cornering, so it is also suited for low-grip tracks. We precisely machined high-quality 2.0mm-thick carbon to make this top deck.

The shock tower Ver.B is made up after continuous feedback from Team INFINITY drivers in the worlds

Newly designed shock positions will provide you stable grip balance in various condition.

Perfectly suitable when you like to make the driving feel milder than kit normal.

It is preventable G-Clip accidentally comming off during running.

Its approx. of 0.2mm thickness provide no weight extendability.

Shutterproof of grease and lenghtening life-span of the parts and maintenance cycle.

Cut about 10mm for each. Fitting on effectively, provide little heating after inserted.

The newly designed gear differential for IF14 offers smooth rotation and high rear traction in all conditions. The differential shafts are now supported by ball bearings for added stability and consistency during runs. Outdrive cups can now be replaced from the outside without the need to open the diff making maintenance quick and easy.